Robot Palletizer Machine For Stable And Efficient Palletizing

A Robot Palletizer Machine is used to stack bags, boxes, or other packaged products onto pallets in a fast and stable way. It is also known as a planar joint industrial robot. This type of machine helps factories reduce manual labor and improve palletizing accuracy.

With automatic control and flexible movement, the Robot Palletizer Machine is suitable for many industries that need continuous and safe palletizing operations.

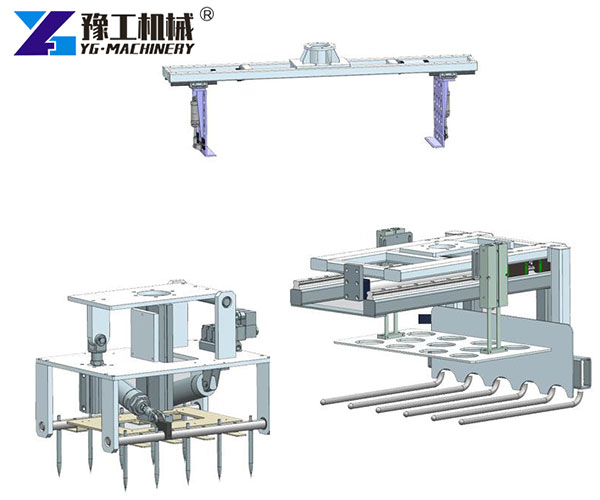

What Is A Robot Palletizer Machine

A Robot Palletizer Machine is an automated industrial robot designed for palletizing tasks. It uses a planar joint structure to move products from a conveyor to a pallet in a precise order.

Main characteristics include:

- Flexible robot arm movement

- Programmable palletizing patterns

- Stable operation for long working hours

Compared with manual palletizing, this solution improves efficiency and reduces worker fatigue.

Key Features Of Robot Palletizer Machine

The Robot Palletizer Machine is designed to meet modern industrial production needs.

Key features include:

- Stable palletizing performance, ensuring neat and consistent stacks

- Low equipment failure rate, suitable for long-term operation

- Energy-saving operation, reducing power consumption

- Wide application range, handling bags, boxes, and heavy loads

These features make the machine a reliable choice for industrial palletizing tasks.

Industrial Robot Palletizer Product Parameters

An industrial robot palletizer is available in different models to meet various load requirements.

| Parameter | YG-50 | YG-150 | YG-260 | YG-500 |

| Load Capacity(kg) | 50 | 150 | 260 | 500 |

| Arm Reach (mm) | 2205 | 2200 | 2212 | 3500 |

| Lifting Stroke (mm) | 1863 | 1900 | 2163 | 2000 |

| Palletizing Speed(cycles/minute) | 6-8 | 6-8 | 1-2 | 1-2 |

| Number of Axes | 4 | 4 | 4 | 4 |

| Total Height (mm) | 3050 | 3200 | 3300 | 3300 |

Working Principle Of Robot Palletizer Machine

The working principle of a Robot Palletizer Machine is based on automatic control and precise positioning.

The basic process includes:

- Products arrive via conveyor

- The robot identifies position and orientation

- Grippers pick up the product

- The robot places it accurately on the pallet

This automated flow ensures stable palletizing quality and reduces human error.

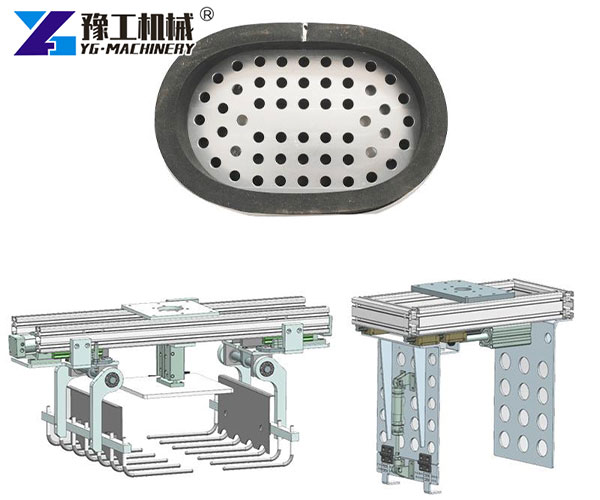

Robotic Palletizing System Grippers And End Effectors

A robotic palletizing system supports different grippers to match various product types.

Common gripper options include:

- Clamp-type grippers for bags and cartons

- Vacuum suction cups for flat surfaces

- Support-type grippers for stable lifting

- Drawer-type grippers for special packaging

- Bag opening grippers for unpacking tasks

- Custom gripper solutions based on product needs

Proper gripper selection improves safety and palletizing efficiency.

Automatic Palletizing Robot Applications By Industry

An automatic palletizing robot is widely used in many industries.

Typical industries include:

- Chemical industry

- Food industry

- Pharmaceutical industry

- 3C manufacturing

- Printing and daily chemical industries

These industries benefit from reduced labor costs and improved production safety.

Robotic Palletizer For Bags And Boxes

A robotic palletizer for bags and boxes handles different packaging types with stable performance.

Bag Palletizing Applications

- Animal feed bags

- Flour bags

- Putty powder bags

Box Palletizing Applications

- Bottled water cartons

- Boards and panels

- Boxes of different sizes

The flexible design allows one machine to handle multiple packaging forms.

Robot Palletizer Machine For Bag Opening And Material Feeding

A Robot Palletizer Machine can also support bag opening and material feeding tasks.

Main functions include:

- Automatic bag opening and feeding

- Polyethylene bag unpacking

- Cement bag unpacking

- Improved feeding safety and dust control

This function is useful for factories that need both unpacking and palletizing automation.

Advantages Of Robot Palletizer Machine Compared With Traditional Palletizers

Compared with traditional palletizing equipment, the Robot Palletizer Machine offers clear advantages.

Main differences include:

- Higher automation level

- Lower labor cost requirement

- Better stability and consistency

- Reduced long-term operating costs

These advantages help factories improve efficiency and control production expenses.

How To Choose The Right Robot Palletizer Machine

Selecting the right machine depends on production conditions and product type.

Important factors include:

- Load capacity requirements

- Packaging type, such as bags, boxes, or barrels

- Production line speed

- Gripper selection

- Industry environment and safety needs

Careful evaluation ensures the machine matches actual production demands.

Typical Use Cases And Project Solutions

Robot palletizer solutions can be configured for different production layouts.

Common project types include:

- Standalone palletizing units

- Integration with conveyor systems

- Integration with packaging lines

- Customized automated palletizing lines

These solutions help factories build efficient and scalable production systems.

Frequently Asked Questions About Robot Palletizer Machine

What products can be palletized?

Bags, boxes, cartons, boards, and heavy industrial loads.

Is the machine difficult to operate?

No. The control system is user-friendly and easy to learn.

Can the grippers be customized?

Yes. Grippers can be designed based on product shape and weight.

Contact us to get special offer now! WhatsApp/WeChat 008613837159132