A Reverse Circulation Drill Rig uses reverse airflow to bring rock chips to the surface. The sample moves inside the drill pipe, not outside. This keeps the sample clean and reduces dust.

Key advantages over DTH or rotary drilling:

- Clean samples with less mixing

- Less water usage in dry regions

- Faster drilling speed in hard formations

This method helps mining companies get better geological data before building large operations. The Reverse Circulation Drill Rig is used worldwide in mineral exploration because it improves sample quality and drilling efficiency.

Contact us to get special offer now! WhatsApp/WeChat 008613837159132

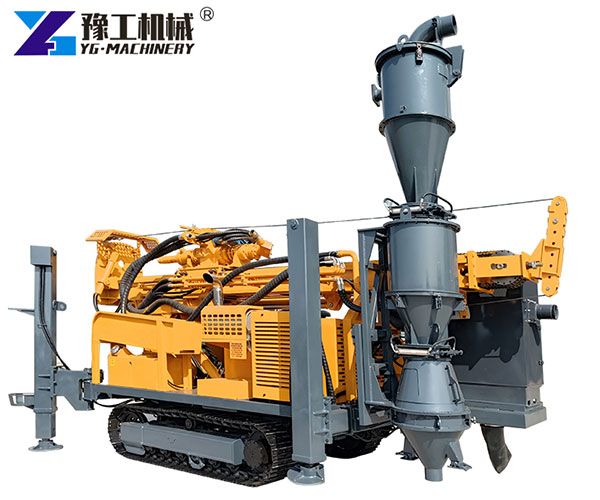

Parameters of A Reverse Circulation Drill Rig

| Model | YG150RC | |

| Drill rig weight(crawler mounted) | kg | 9000 |

| Engine Power | kW | 125 |

| Length × Width × Height (normal) | mm | 6750x2200x2950 |

| Ambient Temperature Range | °C | -10~38 |

| Drill Ability | ||

| Nominal Drill Depth | m | 150 |

| End-hole Diameter | mm | 110-250 |

| Drill angle | ° | -10-90 |

| Horizontal hole height | m | 1.85-2.8 |

| Drill head output | ||

| Max Output Torque | N.m | 8000 |

| Output Rotation Speed(continuity) | rpm | 30 / 60, 54/108rpm |

| Output Rotation Speed(interval) | rpm | 62 / 124105/210rpm |

| Feeding | mm | 3500 |

| Thrust Force | kN | 45 |

| Lifting Capacity | kN | 65 |

| Pipe-puller Device Output | ||

| Output Rotation Speed | rpm | 40 |

| Max Output Torque | N.m | 30000 |

| Hole-through Diameter | mm | 370 |

| Auxiliary Winch | ||

| Pull Force of the First Layer | kN | 11 |

| Rope Diameter | mm | 14 |

| Rope Capacity | m | 60 |

| Engine(Cummins) | 6BTA5.9-C125 | |

| Power | kW | 125 |

| Rotary Speed (Max.) | rpm | 2200 |

| Track Chassis Base | ||

| Walk Speed | Km/h | 1.2 |

| Unit Pressure | MPa | <0.05 |

| Climb Ability | ° | Drill rig weight(crawler-mounted) |

A Reverse Circulation Drill Rig with a strong compressor works faster in hard rock. Good pipe and hammer design also helps samples stay clean during drilling.

How the Reverse Circulation Drilling Method Works

The reverse circulation drilling method is based on airflow and a dual-wall pipe.

Main working steps:

- Compressed air goes down between the two pipe walls

- Air pushes cuttings up through the inner pipe

- Samples pass through a cyclone to separate dust and rock chips

This process reduces dust in the air and improves working safety. The rig can drill deep into different formations, including soft, mixed, and hard rock layers. Clean samples help teams locate mineral resources with higher accuracy.

Key Components Of A Reverse Circulation Drill Machine

A reverse circulation drill machine has strong and reliable parts to support heavy work:

- The engine and air compressor provide power and airflow

- Cyclone and sampling unit collect rock chips

- RC drill pipes, drill bit, RC hammer handle, impact, and wear

- Hydraulic control system and crawler or truck base support field mobility

Not every job site is the same. Many buyers choose crawler rigs for mountains and truck-mounted rigs for long travel distances.

Advantages of Using RC Drill Rig for Mining

An RC drill rig for mining offers many field advantages:

- Higher speed when drilling in mixed or hard rock

- Cleaner samples with less contamination

- Lower water usage is good for dry mining sites

- Better grade control for mine planning

These benefits help reduce operational costs and improve decision-making before large mining investments.

Applications of RC Drilling Equipment

RC drilling equipment is used in many fields because of its strong drilling ability and sample quality:

- Mineral exploration: gold, copper, iron ore

- Grade control in open-pit mines

- Hydrogeological survey and water well drilling

- Construction foundation drilling and quarry development

Many small and large mining companies use this method to evaluate ore bodies before starting production.

Reverse Circulation Drill Rig Price Factors

The price of a Reverse Circulation Drill Rig depends on:

- Engine power, air system, and hammer options

- Drill pipes, bits, and wear parts

- Shipping cost, operator training, and after-sales support

- Cost comparison between RC drilling and standard drilling tools

Choosing the right setup saves money and improves working efficiency in different rock formations.

How to Choose an RC Exploration Drill Rig

An RC exploration drill rig should match your job site and sample needs:

- Ground type and drilling depth

- Sample purity and recovery rate requirements

- Crawler or truck mobility

- Spare parts and support availability

These factors help buyers find the right drilling solution without wasting budget.

Why Choose Us As Your Reverse Circulation Drill Rig Supplier

We supply complete drilling solutions for mining companies and contractors.

- Export experience and international certifications

- Custom configurations for different drilling tasks

- Reliable spare parts support and operator training

- Project cases in Africa, Asia, and South America show strong field performance

Maintenance Tips And Wear-Part Management

Good maintenance keeps the Reverse Circulation Drill Rig running longer:

- Protect the hammer and replace bits on time

- Check compressor pressure daily

- Keep pipes clean to avoid dust and sample mixing

Small checks each day prevent damage, reduce cost, and improve safety on site.

FAQs About Reverse Circulation Drill Rig

Q: Can the rig drill in hard rock?

Yes, with strong airflow and the right hammer, it drills hard rock efficiently.

Q: What air pressure is needed for deep drilling?

High air pressure helps increase drilling speed and sample return.

Q: How to improve sample accuracy?

Use clean pipes, stable airflow, and replace worn bits early.

Q: Can the rig switch to DTH drilling?

Some models can, depending on the configuration.

Q: How long is the delivery and installation?

Delivery time depends on your location. Training support is available after installation.

Contact us to get special offer now! WhatsApp/WeChat 008613837159132