The demand for efficient crushing equipment is rising in construction, mining, and infrastructure projects. A Portable Mobile Rock Crusher is now one of the most popular solutions. It helps reduce transport costs and improves productivity. When equipped with a stone jaw crusher, it becomes the best choice for handling hard stones and construction waste.

Contact us to get special offer now! WhatsApp/WeChat 008613837159132

What Is A Mobile Rock Crusher With a Stone Jaw Crusher?

A mobile rock crusher is a crushing station built on wheels or tracks. Unlike fixed plants, it can move quickly from site to site. The stone jaw crusher is the main machine inside. It breaks large rocks into smaller sizes in the first crushing stage. This makes it perfect for granite, limestone, concrete, and other hard materials.

Types Of Mobile Crusher Machines Provided By YG

YG provides different types of mobile crusher machines to meet various project needs:

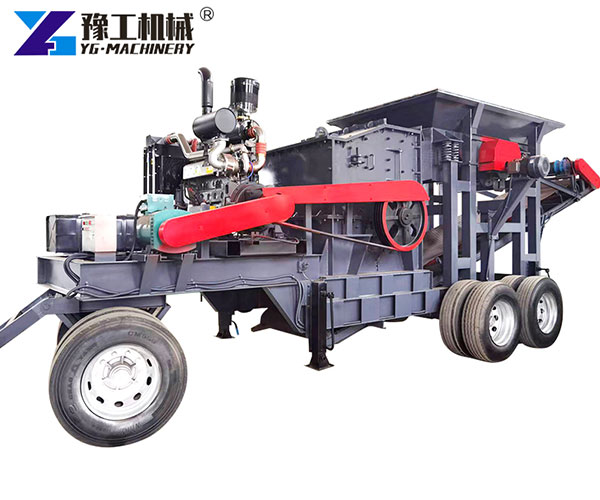

Tire Type Mobile Crusher Machine

This machine is flexible and easy to move. It includes models like the mobile jaw crusher for sale, which uses a fixed jaw and a movable jaw to crush stones. It is widely used for primary crushing in mining, construction waste recycling, and quarry projects.

| Model | 46 | 57 | 69 | 750/1060 | 900/1200 |

| Hop length*width(m) | 5*2 | 3.5*2 | 4*28 | 4.5*2 | 4.5*2.2 |

| Hop thickness(mm) | 8 | 8 | 8 | 10 | 12 |

| I-beam model of chassis | 250 | 250 | 400 | 450 | 620 |

| Conveyor belt length *width(m) | 7*0.8 | 8*0.8 | 8*0.8 | 9*1 | 9*1 |

| Feeder thickness | 0.8 | 0.8 | 1 | 1.2 | 1.2 |

| Motor power | 30kw6g | 55kw6g | 75kw | 1 10KW | 110kw |

| Diesel engine power | 6105 | 6105 | 6110 | 615 | 618 |

| Diesel engine oil volume per hour | 10L | 12L | 14L | 18L | 20L |

| Maximum feed size (mm) | 350 | 450 | 550 | 700 | 800 |

| Head length* width*height(mm) | 1700*1700*1650 | 2000*1950*1900 | 2200*1960*1950 | 2500*2370*2780 | 3200*2820*3260 |

| Discharge port adjustment range(mm) | 40-100 | 50-120 | 75-200 | 80-235 | 186-396 |

| Production output/t/hour | 14-36 | 30-80 | 56-192 | 108-256 | 186-396 |

Mobile Box Stone Crusher

This type has a bin at the top and a crushing box below. A motor or diesel engine drives the hammer inside the box to break stones. It is efficient for crushing both sand and stone, and is suitable for producing high-quality aggregates.

| Model | 800×800 | 800×1000 | 1000×1200 | 1200×1200 | 1200×1500 | 1400×1600 |

| Motor power | 90kw×4G | 110kw×4G | 132kw×4G | 160kw×4G | 185kw×4G | 250kw×4G |

| Diesel power | 195HP | 195HP | 260HP | 330HP | 330HP | 400HP |

| Hopper | 3500×1800×8mm | 3600×2200×8mm | 3600×2200×8mm | 3800×2200×8mm | 3800×2200×8mm | 4000×2400×10mm |

| Hammerhead Weight | 15kg | 15kg | 20kg | 36kg | 36kg | 55kg |

| Total weight | 10t | 12.5t | 14t | 19t | 21t | 26t |

| Belt | 7×0.8m | 8×0.8m | 8×1m | 8×1m | 8×1m | 9×1m |

| Belt conveyor power | 5.5kw | 5.5kw | 7.5kw | 7.5kw | 7.5kw | 7.5kw |

| Tyre model×number | 1100×8pcs | 1100×8pcs | 1100×8pcs | 1000×12pcs | 1100×12pcs | 1100×12pcs |

| Sand capacity | 30t | 45t | 55t | 65t | 80t | 100t |

| Stone capacity | 50t | 70t | 80t | 90t | 120t | 180t |

| Overall size | 10*2.8*3.5m | 11*2.8*3.5m | 11.5*2.8*3.5m | 12*3*3.6m | 12*3*3.6m | 13*3.2*3.7m |

Crawler Portable Crusher Machine

This machine moves on crawler tracks, which gives it strong adaptability on rough terrain. It is known for high performance, reliability, and modern design. It is widely used in road and bridge construction, urban projects, and energy industries for crushing and screening operations.

| Power System | |

| Gasoline engine | 12.5kw/3600r/min |

| Diesel engine | 10.5kw/3600r/min |

| Walking part | |

| Crawler chassis size(mm) | 1220*770 |

| Track model(mm) | 180*72*37 |

| Walking speed(km/h) | 0-3 |

| Track specifications | Steel wire rubber tracks |

| Feeding equipment | |

| Silo volume(m3) | 0.5 |

| Stacking height(mm) | 900-1200 |

| Feeding conveyor(mm) | 1450*400 |

| Jaw plate adjustment range(mm) | 25 |

| Equipment appearance | |

| Working size(mm) | 2950*770*1630 |

| Vertical board inner width(mm) | 410 |

| Transport size(mm) | 2100*770*1760 |

| The total outer width of the guard(mm) | 740 |

| Feed specifications | |

| Feed port(mm) | 200*370 |

| Maximum feed size(mm) | 200 |

| Production capacity(T/D tons/day) | 3-10 |

Key Features & Advantages

The Portable Mobile Rock Crusher brings many advantages:

- Mobility & Flexibility: Easy to move from one project site to another.

- High Crushing Ratio: The stone jaw crusher can handle strong and hard materials.

- Durable & Reliable Design: Built with a strong steel frame and wear-resistant jaw plates.

- Energy Efficiency: Low power use with high production output.

- Easy Operation & Maintenance: Hydraulic system and simple controls save time.

Applications Of Mobile Rock Crusher

The portable rock crushing plant can be used in many projects:

- Construction Waste Recycling: Crushing concrete, bricks, and old building materials.

- Mining Industry: Breaking down ores like granite, iron ore, and limestone.

- Infrastructure Projects: Road, railway, and airport construction.

- Aggregate Production: Producing gravel, sand, and different stone sizes.

Why Choose Our Mobile Rock Crusher With Stone Jaw Crusher

Our machine offers more than standard models:

- Higher output capacity with lower maintenance costs.

- Direct factory supply with competitive price.

- Custom design options to fit different customer needs.

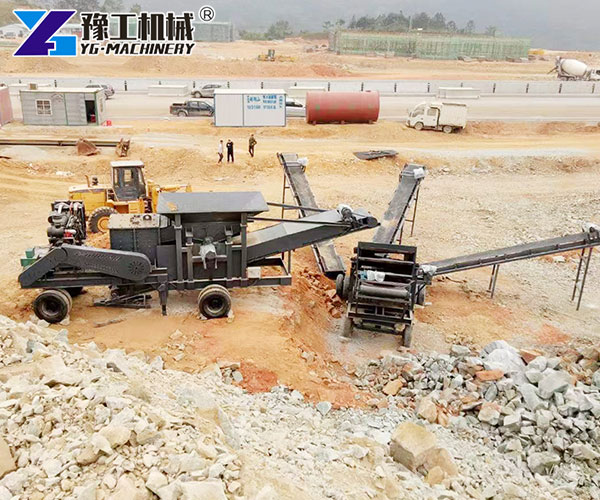

Customer Case Study

A customer in Kenya purchased our rock crusher for a highway project. After installation, the machine processed 200 tons per hour of granite. The customer reported:

- Faster project completion

- 30% lower labor cost

- Significant savings on transport

- Full return on investment within one year

Call To Action

Contact us today to receive a complimentary quotation, a detailed machine configuration, and a video demonstration. We provide OEM and ODM services with global delivery.

Contact us to get special offer now! WhatsApp/WeChat 008613837159132