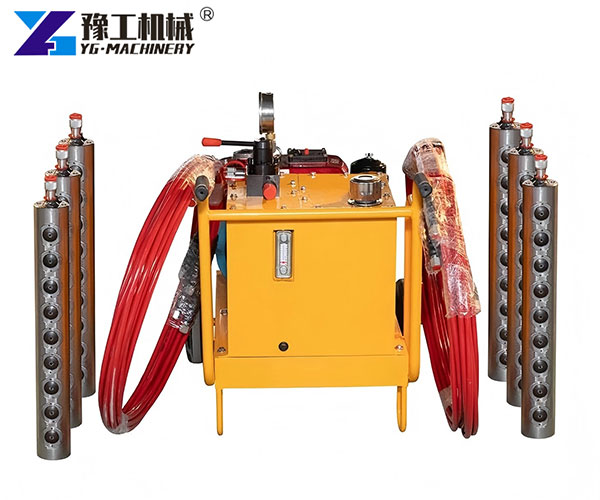

The Piston Rock Splitter is a modern and efficient alternative to traditional drilling and blasting. It is designed for controlled, vibration-free rock and concrete splitting, making it perfect for sensitive work environments such as urban areas, tunnels, or near existing structures.

It delivers precise breaking performance without noise, dust, or flying debris, ensuring a safe and environmentally friendly construction process. This rock-splitter machine is especially useful where explosive methods are restricted.

Technical Parameters Of YG Piston Rock Splitter

| Model | YG-110 | |||

| Length | 900mm | |||

| Punch depth | >1000mm | |||

| Punch diameter | 100mm | |||

| Crack width | 10~20mm | |||

| Splitting time | 10~15s | |||

| Splitting force | s | |||

| Weight | 39Kg | |||

This specification makes the piston rock splitter for sale suitable for quarrying, mining, and concrete demolition in all kinds of terrain.

Benefits Of Choosing YG Piston Type Rock Splitter

The YG Piston Rock Splitter brings strong performance and cost-effective advantages to every project.

Key benefits include:

- Eco-friendly: No noise, vibration, or dust pollution.

- Accurate control: Ideal for precise engineering and controlled breaking.

- Low operating cost: Reduces manpower and minimizes wear on tools.

- Safe operation: Perfect for urban or confined spaces.

- High productivity: Delivers stable and fast splitting power.

Real-World Applications of the Concrete Splitting Machine

The concrete splitting machine can be used across multiple industries and project types, including:

- Quarrying of large granite or limestone blocks.

- Subway and underground excavation projects.

- Bridge, tunnel, and road foundation work.

- Concrete demolition in residential or urban zones.

- Mining operations requiring non-explosive rock removal.

Its flexibility makes it an essential tool for both small construction teams and large-scale mining operations.

Customer Success Stories

YG’s Piston Rock Splitter has been successfully applied in many global projects:

- Belgium Quarry Project: Increased rock extraction efficiency by 35%, reducing project time significantly.

- Thailand Highway Project: Replaced chemical cracking, cutting the total project cost by 20%.

Both clients praised the machine’s reliable performance, stability, and ease of use.

How To Choose The Right Rock Splitter For Your Project

Before purchasing, consider the following factors to select the best hydraulic rock splitter for your needs:

- Evaluate rock hardness and thickness.

- Choose the right hole diameter and splitting depth.

- Decide between single-piston or multi-piston types.

- Match the splitter with a compatible YG hydraulic power station.

Selecting the right configuration ensures higher efficiency and longer machine life.

YG’s Service & Support

YG Machinery not only provides reliable piston rock splitter equipment but also ensures full customer support from pre-sale consultation to after-sales service.

Our services include:

- Comprehensive technical training before shipment.

- Global delivery and spare parts supply.

- Online support and lifetime maintenance guidance.

With years of experience in hydraulic machinery, YG guarantees that every customer receives the best performance and service value.

Contact us to get special offer now! WhatsApp/WeChat 008613837159132