A Pinch Bottom Bag Making Machine forms folded-bottom kraft paper bags with strong sealing edges. These bags are called pinch-bottom bags because the end is folded and glued tightly. This shape is trusted for food-grade packaging since it protects taste and freshness. Bakeries, coffee shops, gourmet food brands, and retail stores choose it for high shelf appeal and clean product presentation. A Pinched-bottom paper bag making machine helps small brands reach market needs with stable quality and lower packaging cost.

Contact us to get special offer now! WhatsApp/WeChat 008613837159132

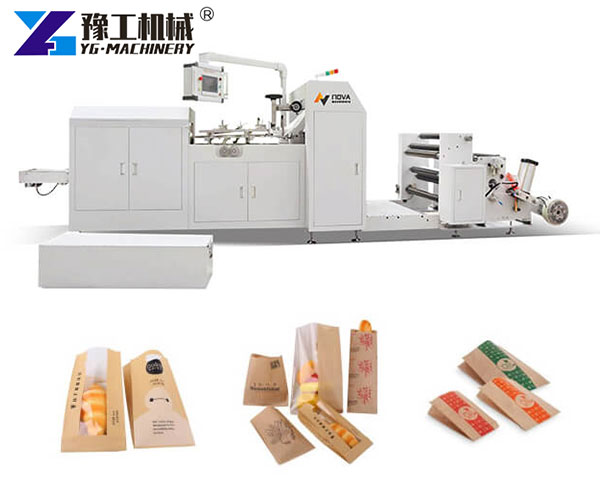

Bag Types Produced By Pinch Bottom Bag Making Machine For Sale

A Pinch Bottom Bag Making Machine for Sale makes many food and retail paper bags:

- Small and medium kraft paper bags for dry food

- Side-gusset bags for roasted coffee beans and loose tea

- Flat-bottom bags for take-out food

- Grease-proof bags for bakery products and pastries

- Window paper bags for snacks, nuts, and dried goods

Main Advantages of Pinch Bottom Paper Bags

Pinch-bottom bags stay popular because they work well with food and daily-use snacks.

Key advantages include:

- Strong sealing keeps the aroma and freshness inside

- A stable bottom shape helps the bag stand on shelves

- Easy printing supports brand logos and labels

- Kraft and recycled paper options meet eco standards

- Works with inner PE coating or foil for barrier needs

- Better protection than flat paper envelopes for snacks

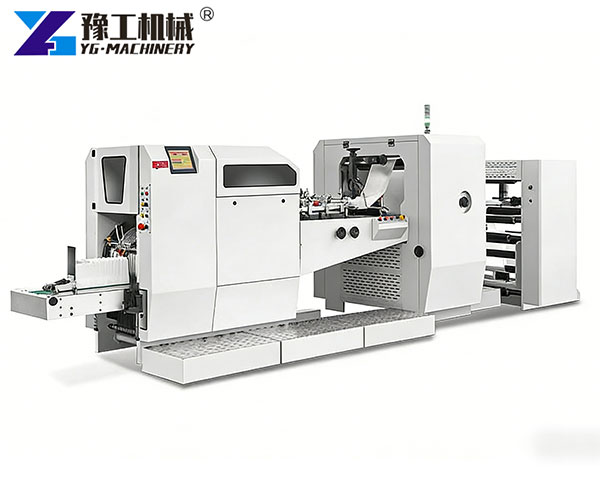

Machine Features & User Benefits — Valve Paper Bag Machine

A valve paper bag machine supports extra forming options and helps users reduce packaging time.

Main features include:

- Adjustable sizes for small retail packaging orders

- High-speed production to reduce the cost per piece

- Inline printing and die-cutting for fast branding

- Clean forming lowers contamination risk

- Optional window unit improves shelf visibility

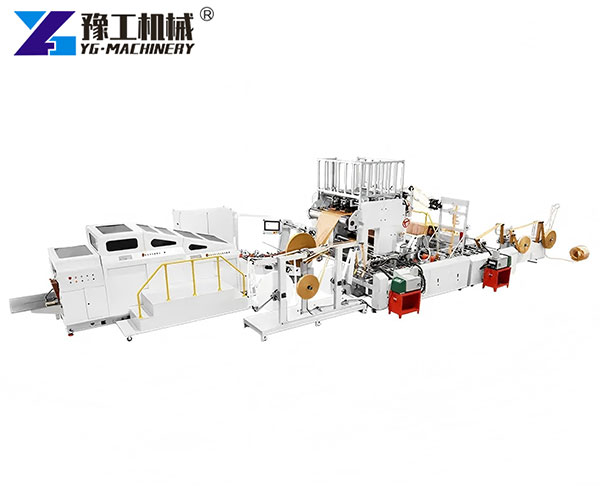

Food And Retail Packaging Uses — V Bottom Paper Bag Machine

A V-bottom paper bag machine supports common retail sizes used in:

- Specialty coffee and tea shops

- Biscuit, candy, and snack brands

- Bakeries and chocolate stores

- Dried fruit and nut retailers

- Organic food stores and local markets

These uses match daily consumer needs and do not involve industrial powder or pet food packaging.

How To Choose A Pinched-Bottom Paper Bag Making Machine

When selecting a Pinched-bottom paper bag-making machine, buyers look at:

- Bag size range and gusset depth

- Paper type: kraft or coated food-grade paper

- Window or non-window forming options

- Flexo or offset printing method

- Daily output needs and cost per unit

- Local raw material supply for long-term production

Business Value For Small Food Packaging Brands

A Pinch Bottom Bag Making Machine supports business growth:

- Helps new food brands enter retail shelves fast

- Lower MOQ supports seasonal or custom product launches

- Attractive packaging increases repeat purchases

- Sustainable materials match EU and US eco policies

FAQ — Folded Bottom Food Packaging Bags

- Can the bags hold oily food?

Yes, with grease-proof or PE lining. - Do the bags support heat sealing?

Yes, with inner film lining. - What is the max fold width?

Depends on the model and the bag size range. - Can printing support food QR traceability?

Yes, for tracking codes and data. - What certifications are accepted for food contact paper?

FDA, FSC, EC food-grade standards.