What Is An Oil Tank Cleaning Robot

An Oil Tank Cleaning Robot is an automated machine designed to clean oil storage tanks without human entry. It replaces manual cleaning work inside confined and dangerous tank spaces. This solution improves safety, reduces downtime, and increases cleaning efficiency.

Compared with traditional cleaning methods, a modern tank cleaning robot offers clear benefits:

- No need for workers to enter the tank

- Stable and repeatable cleaning quality

- Lower labor and safety management costs

This equipment is widely used in oil depots, refineries, and industrial storage facilities where safety and efficiency are critical.

Oil Tank Cleaning Robot Parameter:

| Dimension: | 1220*890*520mm | Speed: | 2.5-4KM/h |

| Self Weight: | 120kg | Designed Load: | 100-300kg |

| Waterproof: | IP68 | Rated Torque: | 100-500 NM |

| Track Width: | 130mm | Reducer Efficiency: | 65-85% |

| Gear Ratio: | 1:10-1:40 | Motor Voltage: | 380ACV (customized as local voltage) |

| Motor: | 0.75-1.5KW*2 | Climbing Ability: | ≤30°(can climb stairs) |

| Motor Rated Speed: | 1500r/min | Maximum Span: | 620mm |

| Cable Control Distance: | Standard 50m, maximum 150m | Over-Obstacle Capacity: | 130mm |

| Maximum Underwater Depth: | 30m | Power Supply: | Generator or 380V power supply |

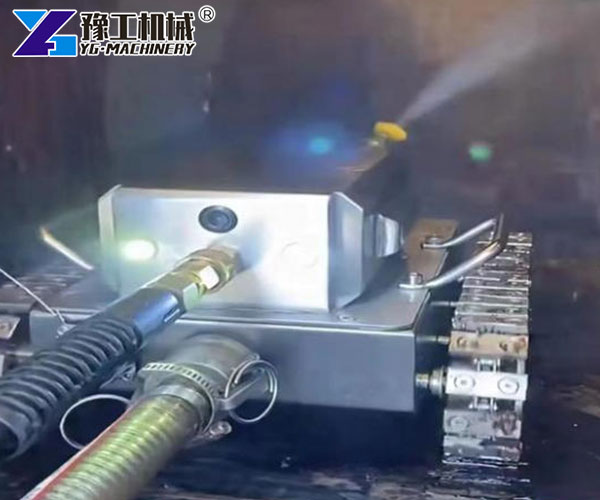

Working Principle Of Oil Tank Cleaning Robot

The Oil Tank Cleaning Robot works by moving inside the tank and spraying high-pressure cleaning fluid onto tank walls and floors. The robot is controlled remotely, allowing operators to stay outside the tank at all times.

The working process usually includes:

- Robot positioning inside the tank

- Rotating spray nozzles remove oil residue

- Continuous movement to cover the full tank area

- Collection or discharge of waste liquid

This automated process makes refinery tank cleaning safer and more controlled, even in harsh environments.

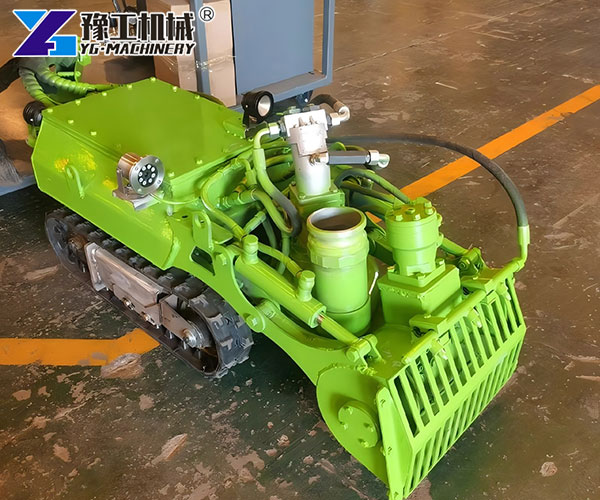

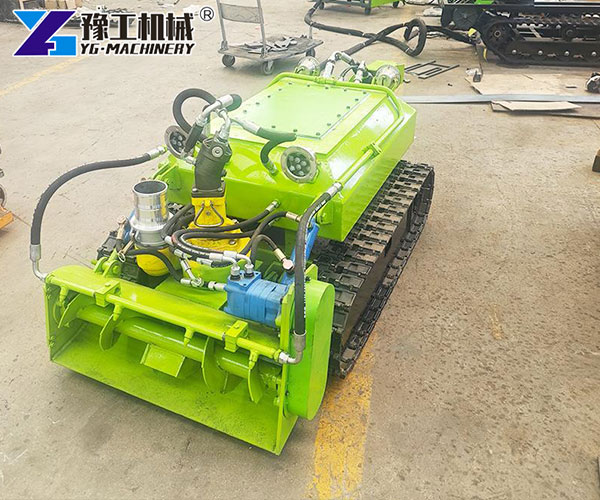

Main Components Of Industrial Tank Cleaning Robot

A reliable industrial tank cleaning robot is built with strong and durable components to handle oil residue and corrosive conditions.

Key components include:

- Robot body with drive and movement system

- High-pressure rotating cleaning nozzles

- Remote control and monitoring unit

- Sealed structure for oil and water resistance

- Safety protection and emergency stop system

Each component is designed to ensure stable operation and long service life during continuous tank cleaning work.

Applications In Refinery Tank Cleaning

The Oil Tank Cleaning Robot is suitable for many industrial applications, especially where safety rules are strict.

Common application areas include:

- Oil storage tanks in refineries

- Crude oil and fuel storage terminals

- Chemical and petrochemical plants

- Large industrial storage tanks

For refinery tank cleaning, the robot helps reduce shutdown time and improve cleaning quality, making it a practical solution for maintenance teams.

Advantages of the YG Tank Cleaning Robot

Our Tank Cleaning Robot is designed to meet real industrial needs and international safety standards.

Main advantages include:

- No human entry into hazardous tanks

- High cleaning efficiency and even results

- Reduced labor and safety risks

- Suitable for different tank sizes and oil types

- Easy operation with the remote control

These benefits make our tank cleaning robot a strong choice for long-term industrial use.

How To Choose The Right Tank Cleaning Robot

Selecting the right tank cleaning robot depends on your specific project requirements.

Key factors to consider:

- Tank diameter and height

- Type of oil residue inside the tank

- Required cleaning speed and efficiency

- Level of automation and control

A proper evaluation helps ensure the robot matches your working conditions and delivers the best performance.

Oil Tank Cleaning Robot Price Factors

The oil tank cleaning robot price depends on several technical and service-related factors.

Main pricing factors include:

- Robot size and cleaning capacity

- Automation level and control system

- Material quality and protection design

- Customization and after-sales support

Understanding these factors helps buyers balance initial cost and long-term value.

Why Choose YG Industrial Tank Cleaning Robot

Our Oil Tank Cleaning Robot is built based on real industrial project experience and customer feedback.

Reasons customers choose us:

- Proven performance in industrial tank cleaning robot projects

- Support for customized solutions

- Stable quality control and testing process

- Export-ready design for global markets

We focus on safety, reliability, and practical performance for every project.

FAQ About Cleaning Robot

Can the robot clean different tank sizes?

Yes, the robot can be adjusted or customized for various tank dimensions.

Is it safe for explosive environments?

The robot is designed with safety protection for hazardous oil tank conditions.

How difficult is the operation?

A remote control makes operation simple and reduces training time.

Is overseas service available?

Technical support and guidance can be provided for international projects.

Contact us to get special offer now! WhatsApp/WeChat 008613837159132