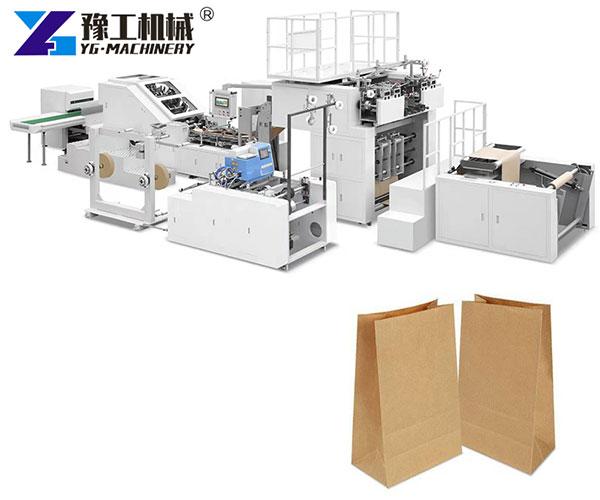

A Flat Bottom Paper Bag Machine helps brands make strong and stable paper bags that stand up straight and hold more weight. Many users choose this machine to replace plastic bags with eco-friendly paper bags. This machine supports fast output, custom sizes, and long working time, which helps factories meet growing packaging demand in retail, bakery, and takeaway food.

What is a Flat Bottom Paper Bag Machine

The Flat Bottom Paper Bag Machine forms paper rolls into finished bags with a flat base. The bag can stand on its own and open easily for filling.

It offers good shape, clean folding, and stable gluing. Bag sizes and material types can be changed to meet different market needs, from small bakery bags to large shopping bags.

What Types of Products Can a Flat Bottom Paper Bag Machine Manufacture?

A single machine can meet different orders:

- Shopping bags for clothing stores

- Bakery bags and food takeaway bags

- Gift bags with handles

- Paper bags for daily retail use

- Packaging bags for light hardware and parts

Many brands use it to make custom-sized bags so shops can use the same design every season.

Square Bottom Paper Bag Equipment Advantages

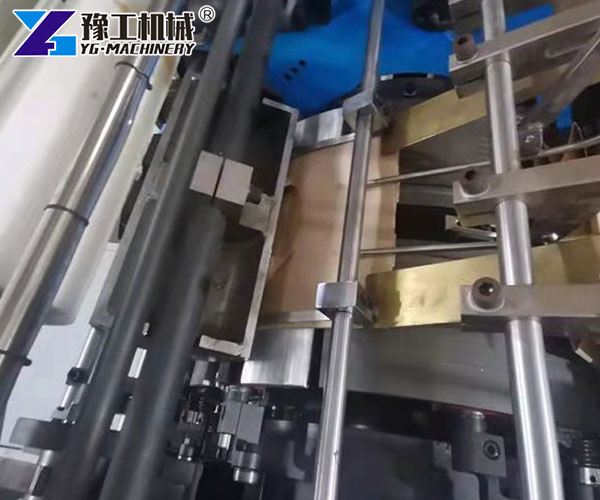

The square-bottom paper bag equipment design brings real working benefits:

- Strong flat bottom that carries more weight without breaking

- Stable base that lets the bag stand upright for display and packing

- High output speed to support large daily production

- Low-waste design to save material and glue

- Easy size change for short or long production runs

- Smooth folding structure that improves brand printing results

This helps manufacturers stay efficient while keeping high-quality bags.

Paper Shopping Bag Production Line Applications

A paper shopping bag production line supports:

- Clothing store packaging with printed logos

- Coffee shops and bakeries are using custom Kraft bags

- Supermarkets that need strong paper bags for daily use

- Gift stores need colorful bags with handles

Many brands now prefer paper shopping bags because they carry a clean brand image and offer more size options than common plastic bags.

How To Choose The Right Flat Bottom Paper Bag Machine

The right choice depends on your factory needs:

- Bag width and bottom width size range

- Daily output and working shift plans

- Printing needs: inline printing or offline printing

- Handle options: twisted handle, flat handle, or no handle

- Material choice: kraft paper or laminated paper

Flat Bottom Paper Bag Machine models with higher automation help reduce manual labor and improve stable output when demand grows.

Kraft Paper Bag Making Machine And Business Value

A kraft paper bag making machine helps you sell into high-value eco packaging markets. Kraft bags are strong, reusable, and can replace plastic bags in many cities. Switching to paper supports government rules and brand image goals.

Main business value:

- Higher customer loyalty with eco packaging

- Wider sales in the retail and food industries

- Stronger material helps reduce bag returns

- Easier printing helps build brand design

Eco-Friendly Paper Bag Manufacturer Benefits

As an eco-friendly paper bag manufacturer, you can:

- Meet rising demand from retail and e-commerce

- Sell bags to stores that must reduce plastic

- Offer fast custom printing service to small buyers

- Add handles and color options to grow value per order

Factories using the Flat Bottom Paper Bag Machine often reach stable long-term orders because buyers repeat their designs every season.

Frequently Asked Questions

Q: What material works best for this machine?

A: Kraft paper is the most common because it is strong and eco-friendly.

Q: Can I make different bag sizes?

A: Yes, size change is simple, and different molds support many sizes.

Q: Does the machine support printing?

A: Both inline and offline printing can be used, based on your workflow.

Q: Is the bottom strong enough for heavy items?

A: Yes, the flat bottom design supports stable stacking and higher weight.

Contact us to get special offer now! WhatsApp/WeChat 008613837159132