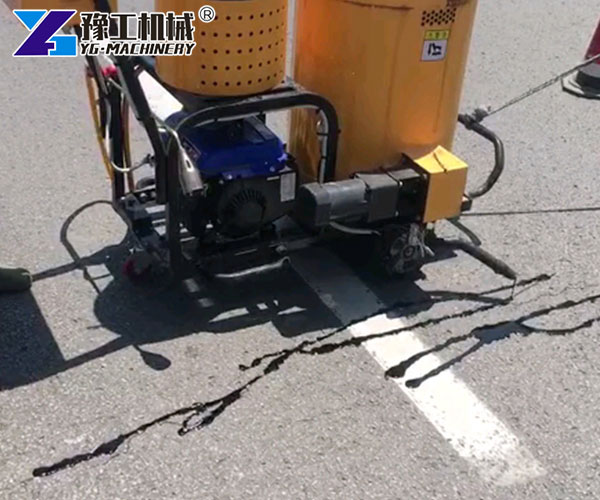

An Asphalt Crack Filler Machine is a road repair tool used to fill and seal cracks in asphalt or concrete pavement. It melts crack sealant and applies it directly into surface cracks to prevent water damage and extend the road’s life. These machines are widely used in municipal, commercial, and highway maintenance work.

They are compact, easy to operate, and help maintain road safety by stopping crack growth early.

Contact us to get special offer now! WhatsApp/WeChat 008613837159132

Parameters of Asphalt Crack Filler Machine

| Model | YG-50L | YG-80L | YG-100L |

| Hopper volume | 50L | 80L | 100L |

| Discharge method | Self flow | Asphalt pump feed | Asphalt pump feed + hand-held tube |

| Heating method | Liquefied gas | Liquefied gas + heat transfer oil | Italian diesel burner, heat transfer oil cycle heating |

| Temperature control | Temperature sensor 180 ° (temperature control call) | Temperature sensor 180 ° (temperature control call) | Automatic temperature control system |

| Filling speed | 10m/min | 15m/min | 20m/min |

| Length of sealing pipe | —— | —— | 5m |

| Walking mode | Push-type + brake device | Push-type + brake device | Push-type + trailer |

| Mixing method | Manual mixing | Manual mixing | Electric stirring |

| Power Configuration | Solar panels + batteries | Solar panels + batteries | Import 2KW generator |

| Dimensions | 1200*700*1200mm | 1200*700*1200mm | 1750*786*1200mm |

| Weight | 120kg | 150kg | 220kg |

Key Features Of Asphalt Crack Filler Machine

The Asphalt Crack Filler Machine is designed for speed, efficiency, and ease of use. Its core features include:

- Efficient Heating System: Uses a propane or diesel burner to melt crack filler quickly.

- Simple Operation: Easy controls for sealing, with adjustable flow rate.

- Mobility: Comes with wheels or a trailer for easy transport on roads.

- High Capacity: Can hold large amounts of sealant for long jobs.

- Durable Build: Made from steel for long-term use in tough conditions.

These features make it ideal for both small local jobs and large highway repairs.

Concrete Joint Sealing Machine For Pavement Repair

A Concrete Joint Sealing Machine works similarly to the asphalt version but is optimized for concrete surfaces. It ensures that expansion joints and cracks are sealed tightly to avoid water intrusion.

Use this machine to:

- Seal cracks in concrete roads, sidewalks, and airport runways

- Improve surface durability and prevent edge spalling

- Increase the service life of concrete infrastructure

It’s a must-have tool for concrete maintenance contractors.

Where Can You Use An Asphalt Crack Sealing Machine?

Asphalt Crack Sealing Machines are suitable for a wide range of applications. These include:

- City Streets: Regular repair of aging asphalt surfaces.

- Highways and Expressways: Prevent cracks from growing under heavy traffic.

- Parking Lots: Extend the life of commercial asphalt surfaces.

- Airports: Fix runway joints and surface cracks quickly.

They are used by:

- Road repair companies

- Municipal public works departments

- Building contractors

- Airport maintenance teams

Why Choose Our Asphalt Crack Sealer Machine?

Our Asphalt Crack Sealer Machine offers strong performance and value. Here’s why users prefer it:

- Saves time with fast heating

- Portable and easy to move

- Works on both asphalt and concrete

- Compatible with most sealant types

- Low fuel consumption for cost savings

With this machine, users can handle long sealing projects efficiently and with professional results.

Common Questions About Asphalt Crack Filler Machine

- Q1: What type of sealant does the machine use?

A: It uses hot-pour crack filler made from asphalt rubber or rubberized asphalt. - Q2: Can one person operate the machine?

A: Yes, one person can handle it easily thanks to its simple controls and flow system. - Q3: Does it work on both asphalt and concrete?

A: Yes, it’s effective on both, especially when paired with the proper sealant. - Q4: How long does it take to heat the material?

A: Most machines heat crack filler in 15–30 minutes, depending on the tank size and burner power.

If you want to seal pavement cracks quickly and professionally, our Asphalt Crack Filler Machine is the right choice. Whether you’re a contractor or city worker, this machine saves labor, improves repair quality, and reduces maintenance costs.

Contact us now for your Asphalt Crack Filler Machine quote.

Contact us to get special offer now! WhatsApp/WeChat 008613837159132