The global fast food market continues to grow, and hamburger boxes remain one of the most used food packaging products. Every day, restaurants, delivery services, and takeaway brands need large volumes of strong and clean paper boxes. This stable demand makes automated production a smart choice.

At the same time, paper food packaging is replacing plastic in many regions. Environmental rules and food safety standards in Europe and North America are pushing brands to use recyclable paper boxes. A Burger Box Making Machine helps manufacturers meet these market and policy needs while keeping production costs under control.

What is a Burger Box Making Machine

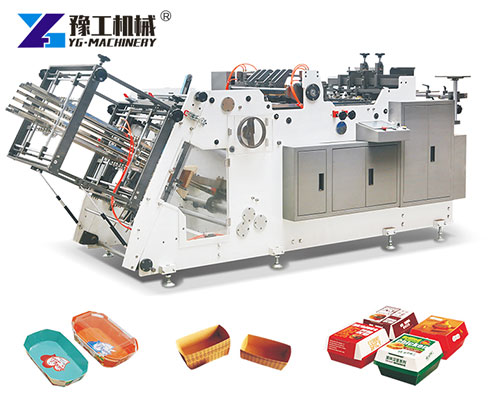

A Burger Box Making Machine is a specialized machine used to form flat paper sheets into finished hamburger boxes through heating, pressing, and folding. It is a key machine in modern food packaging factories.

Core Role In Food Packaging Production Line

In a complete packaging line, this machine:

- Shapes printed and die-cut paper into the final box form

- Controls box size, structure, and forming strength

- Ensures stable output for packing and delivery

It works closely with other equipment, such as printing machines, die cutting machines, and stacking systems to create a smooth workflow.

Burger Box Making Machine Parameter

| Raw Material | 200-600g/m² cardboard |

| Productivity | 60-200pcs/min |

| Power Source | 380V 50Hz |

| Total Power | 5.5Kw |

| Production Size | |

| Box Length | 100-450mm |

| Box Width | 100-600mm |

| Box Height | 15-200mm |

| Degree | 5-40˚ |

| Dimensions | 3600*1200*1800mm |

| Weight | 1800kg |

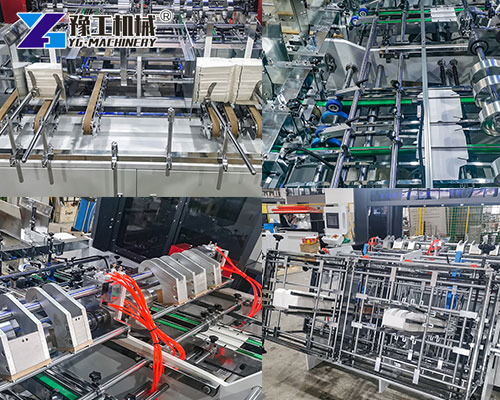

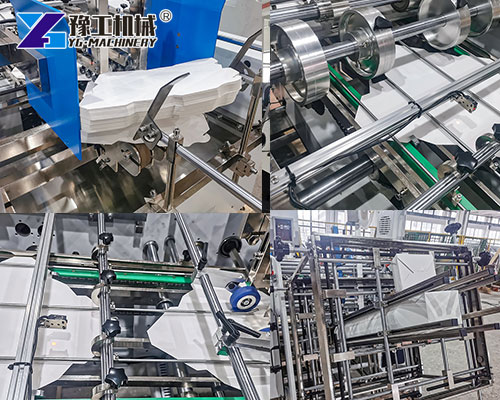

How A Hamburger Box-Making Machine Works

The working process of a hamburger box-forming machine is simple, stable, and easy to control.

Main Working Steps

The standard process includes:

- Paper feeding and accurate positioning

- Heating and pressure forming

- Folding and box shaping

- Finished product output and stacking

This process helps keep every box the same size and shape.

Automatic Vs Semi-Automatic Operation

An automatic machine runs continuously with PLC control and needs fewer workers. A semi-automatic machine needs more manual steps but has lower initial cost. Both options are widely used, depending on factory size and budget.

Key Advantages Of Burger Box Making Machine

Using a Burger Box Making Machine brings clear benefits for packaging manufacturers.

Efficiency And Cost Control

Main advantages include:

- Higher production speed per hour

- Lower labor dependence

- Reduced human errors during forming

Consistent Box Quality

Stable forming ensures:

- Uniform box size

- Strong box corners

- Better stacking and transport safety

This is important for chain restaurants and bulk orders.

Product Features Of Paper Food Box Making Machine

A paper food box making machine is designed to balance speed, quality, and easy operation.

Key Technical Features

Important features include:

- Stable heating system for clean forming

- Strong forming pressure for firm boxes

- Easy mold replacement for different box sizes

- Simple control system for fast parameter adjustment

These features help factories maintain stable production during long working hours.

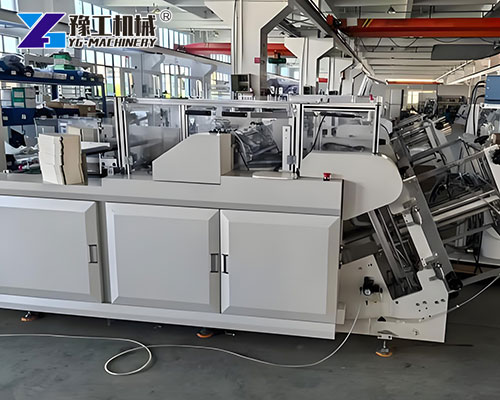

How To Choose The Right Burger Box-Making Machine

Choosing the right machine depends on real production needs, not just price.

Main Selection Factors

Buyers should consider:

- Target output (boxes per hour)

- Paper material type and thickness

- Burger box size and structure

- Factory space, power supply, and operator skills

A well-matched automatic lunch box machine helps avoid waste and improves long-term efficiency.

When A Hamburger Box Making Machine Is Not Recommended

Although widely used, a Burger Box Making Machine is not suitable for every situation.

It may not be the best choice for:

- Very small handmade packaging workshops

- Early-stage testing of special or irregular box designs

- Low-volume custom orders without efficiency requirements

In these cases, manual or simple tools may be more practical.

Application Scenarios

Case 1: Fast Food Packaging Factory

A medium-sized packaging factory supplies hamburger boxes to local fast food brands. By using an automatic forming machine, the factory increased daily output and reduced labor costs. Box quality became more stable, helping win long-term supply contracts.

Case 2: Export-Oriented Paper Box Supplier

An export company producing paper food boxes for overseas markets uses this machine to meet strict size and quality standards. The stable forming process improves packing efficiency and reduces customer complaints.

FAQs about Burger Box Making Machine

What paper materials can be used?

Most machines support common food-grade paperboard used for hamburger boxes.

Can one machine make different box sizes?

Yes. Changing molds allows the production of different sizes.

Is the operation difficult?

No. Basic training is enough for daily operation.

Is it suitable for large orders?

Yes. Automatic models are designed for continuous mass production.

Contact us to get special offer now! WhatsApp/WeChat 008613837159132