Sediment buildup is a common issue in rivers, lakes, and ponds. Over time, silt, sludge, and organic waste reduce water depth, block water flow, and increase maintenance costs. For many project owners, the challenge is not only how to remove sediment, but how to choose a dredging solution that is safe, efficient, and suitable for the site conditions.

Today, dredging is no longer limited to large traditional equipment. Robotic dredging systems offer new options for projects where space, safety, or environmental protection is a concern. Understanding how different dredging methods work helps decision-makers select the right solution instead of relying on outdated approaches.

Common Dredging Challenges in Rivers and Lakes

Most dredging projects face similar challenges, despite each site being unique.

- Sediment accumulation caused by slow water flow or seasonal flooding

- Narrow or shallow waterways that limit access for large machines

- Environmental restrictions in urban or protected water areas

- High safety risks when operators work close to water or underwater

These challenges make it difficult for traditional dredging equipment to perform efficiently in many river and lake maintenance projects.

Traditional Dredging vs Robotic Dredging Solutions

Traditional dredging usually relies on excavators, cutter suction dredgers, or manual cleaning methods. These solutions can remove large volumes of sediment, but they also require significant space, manpower, and setup time.

Common limitations of traditional dredging include:

- Large equipment size and difficult transport

- High fuel and labor costs

- Limited precision in narrow areas

- Higher environmental disturbance

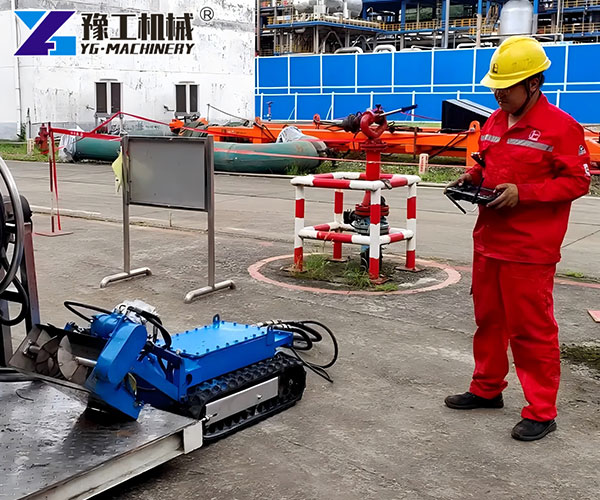

Robotic dredging solutions operate differently. They are remotely controlled, compact, and designed for precise sediment removal. A robotic dredging solution allows operators to work from shore, reducing direct contact with water and improving safety.

For many river and lake projects, robotic dredging provides better control and lower environmental impact compared to traditional methods.

When Is a Dredging Robot Better Than Traditional Dredging?

A dredging robot is not always the best choice, but it becomes highly effective in specific situations.

Robotic dredging is often a better option when:

- Rivers are too narrow or shallow for large dredgers

- Lakes are located in urban or residential areas

- Projects require low disturbance to water ecosystems

- Long-term maintenance is needed instead of one-time excavation

In confined or sensitive environments, dredging robots offer flexibility and safety that traditional equipment cannot easily achieve.

Applications Where a Dredging Robot May NOT Be Suitable

Although robotic dredging offers many advantages, it is not the best solution for every project. Understanding its limitations is crucial for making informed equipment selections.

A dredging robot may not be suitable in the following situations:

- Large-scale capital dredging projects

When massive volumes of sand or gravel must be removed in a short time, traditional cutter suction dredgers are usually more efficient. - Very deep water environments

Extreme water depth may exceed the operating range of standard robotic systems. - Hard or compacted sediment layers

Rock, dense clay, or cemented material often requires heavy mechanical cutting or blasting methods. - Projects with poor power or logistics support

Remote sites without a stable power supply or maintenance access may limit robotic operation.

In these cases, conventional dredging or hybrid solutions may offer better performance and cost control.

Environmental and Safety Advantages of Robotic Dredging

Environmental protection and worker safety are key concerns in modern dredging projects, especially in Europe and other regulated regions.

Robotic dredging offers clear advantages:

- Reduced water turbidity during operation

- Minimal damage to aquatic plants and habitats

- Lower fuel consumption and noise

- Improved operator safety through remote control

Because operators do not need to enter the water, robotic dredging greatly reduces risks in polluted water, deep sediment zones, or confined spaces such as industrial tanks.

Case Insight: Portable Dredging Solution for a European River Project

In many European river projects, strict environmental rules and limited access make traditional dredging difficult. Portable robotic dredging solutions are often selected to meet these challenges.

In a river maintenance project in Sweden, a portable dredge was used instead of a large dredger. The river section was narrow, and heavy equipment could not enter the site easily. The robotic system allowed:

- Easy transportation to the project area

- Fast setup without major civil work

- Controlled sediment removal with minimal disruption

This case shows how choosing the right dredging solution can improve efficiency while meeting local regulations.

How to Select the Right Dredging Equipment for Your Project

Selecting dredging equipment should start with site analysis rather than machine size.

Key factors to consider include:

- Water depth and channel width

- Type of sediment, such as silt, sludge, or sand

- Environmental and safety requirements

- Project duration and maintenance frequency

In many situations, a combination of traditional and robotic dredging provides the best balance between cost and performance. Making a clear comparison before purchasing equipment helps avoid unnecessary investment and operational problems.

Making Smarter Dredging Decisions

Dredging projects differ greatly depending on location, sediment type, and environmental conditions. Rivers, lakes, ponds, and industrial water bodies all require tailored solutions. By understanding the strengths and limits of each dredging method, project owners can reduce risk and improve long-term results.

Robotic dredging solutions continue to gain attention because they address modern challenges in safety, precision, and environmental control. For many river and lake maintenance projects, they represent a practical and future-ready approach.

Contact us to get special offer now! WhatsApp/WeChat 008613837159132