A Swedish quarry customer ordered a rock splitter from YG Machinery, received the equipment smoothly, and has already put it into use in their quarry project.

Project Background And Rock Splitting Demand In Sweden

Sweden has many construction and quarry projects that involve hard rock. Granite and other high-strength rock layers are very common in this region. These materials are difficult to break and require reliable solutions.

At the same time, Sweden has strict rules on environmental protection and job site safety. Many projects are subject to limits on noise, vibration, and dust. Due to these rules, traditional blasting is not always the best choice. Blasting often causes strong vibration and loud noise, and the approval process can take a long time.

Because of these challenges, more Swedish quarry operators prefer non-blasting solutions. Controlled rock splitting allows them to break rock safely and efficiently. For this reason, demand for modern rock splitting equipment continues to grow in Sweden.

Customer Requirements And Technical Challenges

Before placing the order, the customer shared clear expectations for the project. The rock splitter machine needed to work well in very hard granite and remain stable during long working hours.

The main requirements included:

- Suitable for high-hardness rock conditions

- Safe operation with simple maintenance

- Compatible with an external hydraulic power source

However, the project also had several challenges:

- Very low temperatures during the Swedish winter

- High requirements for durability and long service life

- Concerns about overseas after-sales support and training

These factors made the selection of a reliable rock splitter supplier especially important for the customer.

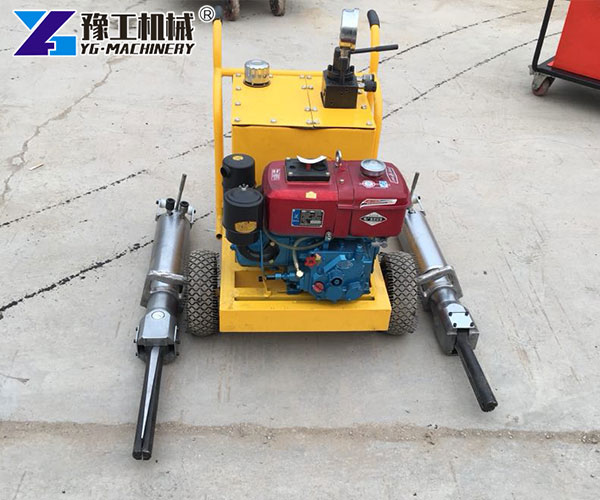

Matching The Right Rock Splitter Machine

After understanding the project details, YG Machinery recommended a suitable rock splitter machine based on the drilling hole size and rock strength. The goal was to provide a strong splitting force while keeping the operation simple and safe.

Key features of the recommended solution included:

- High-strength alloy wedges for fast and clean splitting

- Stable structure for continuous quarry work

- Easy connection with hydraulic power units

This solution helped the customer control crack direction and reduce unwanted damage to the surrounding rock. Compared with blasting, it offered better safety and higher working accuracy.

The Technological Parameters of Hydraulic Rock Splitter:

| Model | YG-450 |

| Wedge Length(mm) | 450mm |

| Piston Stroke(mm) | 90/220mm |

| Drilling Depth(mm) | >900mm |

| Punching Diameter(mm) | 46mm |

| Crack Width(mm) | 10-20mm |

| Cleavage Time(s) | 10-15/s |

| Splitting Force(T) | 800t |

| Weight(kg) | 260kg |

Hydraulic Rock Splitter Solution For Quarry Projects

For this Swedish quarry, a hydraulic rock splitter was the ideal choice. Hydraulic power provides a strong and steady force, which is necessary when working with granite.

Main advantages of this solution:

- No blasting, low vibration, and low noise

- Controlled cracking for safer quarry operations

- Suitable for quarrying, foundation work, and tunnel projects

With these benefits, the equipment matched both local regulations and the customer’s production goals.

YG After-Sales Service And Technical Support

YG Machinery understands that overseas customers care greatly about service. To reduce the customer’s concerns, we provided full after-sales support throughout the project.

Our service included:

- Clear operation manuals and drilling guidance

- Remote technical support during installation and use

- Practical advice on splitting pressure and hole spacing

With this support, the customer learned how to use the rock splitter for sale efficiently and avoided unnecessary downtime or trial-and-error costs.

Customer Feedback From Sweden

After the equipment was put into operation, the customer shared positive feedback. The splitter worked well in granite and met all local safety and environmental standards.

Customer feedback highlighted:

- Stable splitting results with high efficiency

- Reliable performance during daily quarry work

- Good support and fast technical response

The equipment has been successfully used in real quarry operations, and the customer has shown interest in future cooperation.

Looking for a reliable rock splitter for sale? Contact us to get a professional solution based on your project conditions.

Contact us to get special offer now! WhatsApp/WeChat 008613837159132