A Toilet Tissue Making Machine is a fully automatic system that turns jumbo tissue rolls into smaller rolls or folded paper products. It is designed to improve speed, reduce labor, and ensure stable quality.

Contact us to get special offer now! WhatsApp/WeChat 008613837159132

Toilet Tissue Making Machine Parameter

| Machine model | YG-1575/1880/3000 |

| Base paper roll diameter | 1200mm (Please specify) |

| Jumbo roll core diameter | 76mm (Please specify) |

| Punch | 2-4 knife, spiral cutter line |

| Control system | PLC control, variable frequency speed control, and touch screen operation |

| Product range | core paper, noncore paper |

| Drop tube | manual and automatic (optional) |

| Working speed | 150-280 m/min |

| Power | 220V/380V 50HZ |

| Embossing | Single embossing, double embossing |

Toilet Paper Roll Making Machine Types

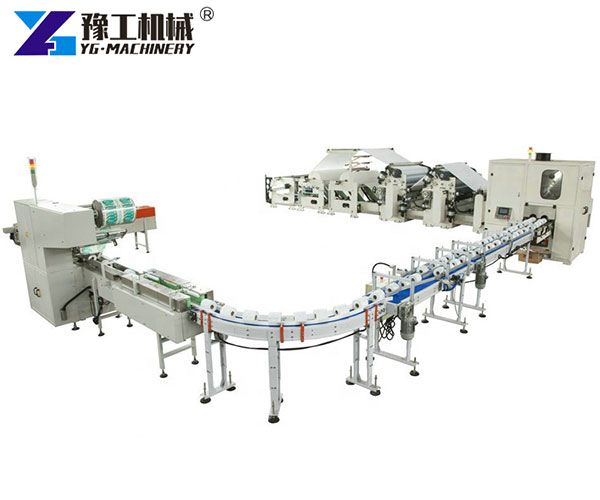

Fully Automatic Toilet Paper Machine

A fully automatic production line is usually composed of the following equipment:

- Fully Automatic Rewinding Machine

- Rewinds jumbo rolls into smaller toilet paper rolls, automatically completing perforation, embossing, and rewinding.

- Features high automation, fast efficiency, and consistent product size.

- Fully Automatic Band Saw Cutting Machine

- Automatically cuts long toilet paper logs into individual rolls.

- Ensures stable operation and maintains neat cutting edges without requiring manual intervention.

- Fully Automatic Single Roll or Multi-roll Packaging Machine

- Packs toilet paper rolls either individually or in multiple packs as required.

- Automatically completes bagging, sealing, and organizing, which significantly reduces labor and improves efficiency.

✅ The fully automatic line requires almost no manual operation from rewinding to cutting and packaging. It is ideal for large-scale factories, helping reduce labor costs, increase production output, and maintain high consistency.

Semi-Automatic Production Line

A semi-automatic production line typically includes the following equipment:

- Toilet Paper Rewinding Machine

- Rewinds jumbo rolls into finished toilet paper rolls with perforation and embossing functions.

- Requires manual assistance and has a lower automation level compared with fully automatic machines.

- Manual Band Saw Cutting Machine

- Used for cutting toilet paper logs into small rolls.

- Operated manually with feeding required; cutting efficiency and precision are relatively limited.

- Pneumatic Water-Cooling Sealing Machine

- Used for simple sealing of single rolls or small packages.

- Features pneumatic control and water-cooling technology, ensuring firm sealing, but requires manual operation for packaging.

✅ The semi-automatic line has a lower investment cost and more flexible operation, but requires more manual labor. It is suitable for small to medium-sized paper mills or businesses with limited budgets.

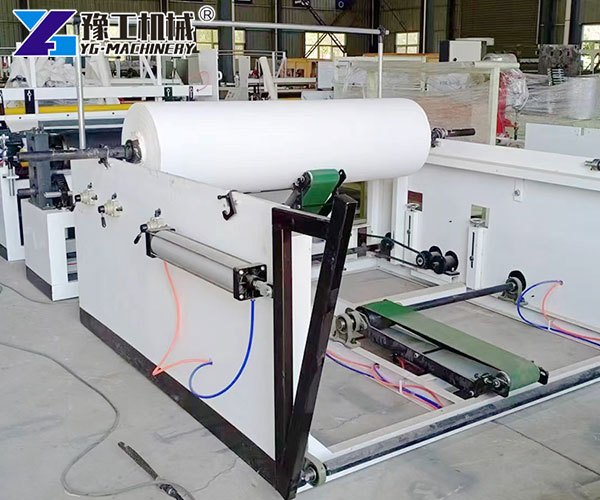

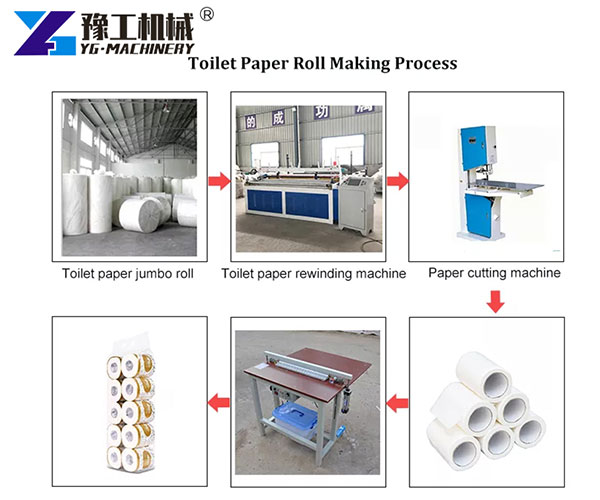

How Does The Toilet Tissue Making Machine Work?

The production flow is simple and clear:

- A jumbo paper roll is placed on the machine.

- Paper goes through embossing or perforation.

- The sheet is rewound into a roll.

- Rolls are cut into the required sizes.

- Finished rolls are packed automatically.

Modern machines are often designed as a tissue paper production machine or a toilet paper roll making machine with:

- PLC control for precise operation.

- Adjustable speed to meet output needs.

- Energy-saving features for lower costs.

Key Advantages Of the Toilet Tissue Making Machine

Using a Toilet tissue-making machine brings clear benefits to factories and businesses:

- High Efficiency: Suitable for mass toilet paper production with stable output.

- Energy Saving: Smart design reduces waste and lowers power use.

- Better Quality: Clear embossing, smooth cutting, and neat packaging.

- Flexible Options: Support for different sizes, patterns, and packaging styles.

These features make it an ideal choice for companies wanting reliable and cost-effective production.

Applications of the Toilet Paper Making Machine

The machine is widely applied in:

- Tissue paper factories.

- Household goods manufacturers.

- Large retail and supply chains.

As a toilet paper manufacturing machine and tissue converting equipment, it also offers strong market potential:

- Global toilet paper demand continues to rise.

- Stable consumption makes it a safe investment.

- Long-term growth ensures sustainable returns.

How To Choose The Right Toilet Tissue Making Machine

When selecting a machine, buyers should consider:

- Capacity Needs: Choose small, medium, or large production lines.

- Functions: Decide if embossing, color printing, or automatic packaging is required.

- Investment & ROI: Compare equipment price, running cost, and expected profit.

- After-Sales Service: Installation, operator training, and long-term maintenance support.

A suitable Toilet Tissue Making Machine not only improves production but also reduces cost and raises competitiveness in the market.

The Toilet Tissue Making Machine is efficient, eco-friendly, and stable for long-term use. It helps businesses expand production, reduce costs, and meet rising demand.

👉 Contact YG today to get a custom plan and the latest price for your Toilet Tissue Making Machine.

Contact us to get special offer now! WhatsApp/WeChat 008613837159132