The demand for safe and eco-friendly packaging is rising fast as global egg consumption increases every year. Farmers and suppliers need packaging that protects eggs during transport and storage. An egg tray production machine offers a modern, cost-effective, and sustainable way to meet this need. It transforms waste paper into durable trays, helping reduce costs and improve efficiency.

Contact us to get special offer now! WhatsApp/WeChat 008613837159132

What Is an Egg Tray Production Machine?

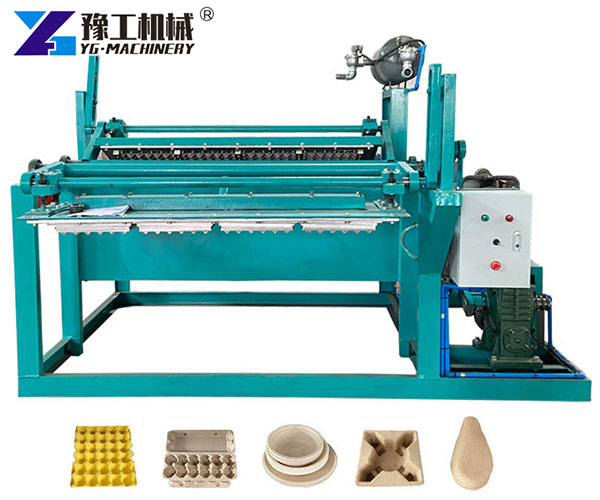

An egg tray production machine is designed to convert recycled paper into molded trays that hold eggs safely. The machine includes four key systems:

- Pulping system – breaks down waste paper into pulp.

- Forming system – molds the pulp into trays with high precision.

- Drying system – dries the trays using natural or mechanical methods.

- Stacking and packing system – collects and organizes finished trays.

This solution is energy-saving, eco-friendly, and suitable for both small farms and large industrial plants. It works as a reliable automatic egg tray machine for mass production.

Technical Specifications Of Paper Egg Tray Production Line

Here are common models and specs. This table helps you compare quickly.

| Model | Output(pcs/h) | Mould Quantity | Total Power(kW) | Raw Materials (kg/h) |

| DT-1*3 | 1000 | 1*3+3 | 41 | 23.8 |

| DT-1*4 | 1500 | 1*4+4 | 41 | 28.4 |

| DT-3*4 | 2000 | 3*4+3 | 53.7 | 32.57 |

| DT-4*4 | 3000 | 4*4+4 | 57 | 39.9 |

| DT-4*8 | 4000 | 4*8+4 | 90 | 63 |

| DT-5*8 | 5000-6000 | 5*8+5 | 150 | 105 |

| DT-5*12 | 6000-7000 | 5*12+5 | 153 | 107.1 |

How Does the Egg Tray Making Machine Work?

The production process is simple yet efficient.

- Waste paper is collected and turned into pulp.

- The pulp is filtered and delivered to forming molds.

- The molded trays are dried by natural sun drying, brick kiln, or metal drying line.

- Finished trays are stacked and packaged for use or sale.

Key technologies include automated controls for steady output, durable molds for long life, and energy-saving systems. This makes the machine a strong choice for anyone needing an egg tray-making machine or an advanced pulp molding machine.

Key Benefits Of Using An Egg Tray Production Line

Businesses and farms can gain several benefits:

- Eco-friendly production – uses waste paper and promotes recycling.

- Low cost and high return – reduces packaging expenses while creating profit.

- Flexible design – supports trays for eggs, fruits, shoes, or industrial packaging.

- Strong market potential – rising global demand for egg trays ensures long-term growth.

With these strengths, the egg tray production machine becomes a smart investment in both sustainability and profitability.

Applications Of the Egg Tray Production Machine

The machine is widely used across different industries.

- Poultry farms – for daily egg collection and transport.

- Egg processing plants – to package and sell eggs safely.

- Supermarket supply chains – ensure protection during long transport.

- Extended use – can also produce fruit trays, cup trays, and industrial protective packaging.

Many factories integrate it into a full egg carton manufacturing machine setup or connect it with a complete paper tray production line.

How To Choose The Right Egg Tray Production Machine

When selecting a machine, several factors matter:

- Output capacity – choose from 1000 to 7000 trays per hour.

- Drying method – natural drying for small operations, or advanced metal drying lines for large factories.

- Mold type – customizable molds for egg cartons, fruit trays, or industrial trays.

- After-sales support – reliable suppliers offer installation guidance, training, and spare parts.

Choosing the right model ensures smooth operation and long-term success. An egg carton manufacturing machine with full technical support adds extra security for investors.

The egg tray production machine is eco-friendly, efficient, and cost-saving. It meets global demand for safe egg packaging while opening business opportunities. If you want to build a profitable egg carton-making line, contact YG today to get detailed specifications, machine options, and a full quotation.

Contact us to get special offer now! WhatsApp/WeChat 008613837159132