A rock core drilling machine is a key tool for geology. It drills core samples from rock and soil. These samples help engineers and geologists study layers and find minerals. Global demand is growing for mining, tunneling, and road projects. Our rock core drilling machine meets these needs. We deliver durable rigs for field use.

Parameters of Rock Core Drilling Machine:

| Model | HZ-130Y/130YY | HZ-180Y/180YY | HZ-200Y/200YY |

| Drilling Depth (m) | 130 | 180 | 200 |

| Open Drilling Diameter (mm) | 220 | 220 | 325 |

| Final Hole Diameter(mm) | 75 | 75 | 75 |

| Drill Pipe Diameter(mm) | 42-60 | 42-60 | 42-60 |

| Drill Pipe Inclination (°) | 90-75 | 90-75 | 90-75 |

| Power (kW) | 13.2 | 13.2 | 14.7 |

| Weight (kg) | 920 | 950 | 1150 |

| Dimensions(mm) | 2400*950*1400 | 2400*950*1400 | 2700*950*1770 |

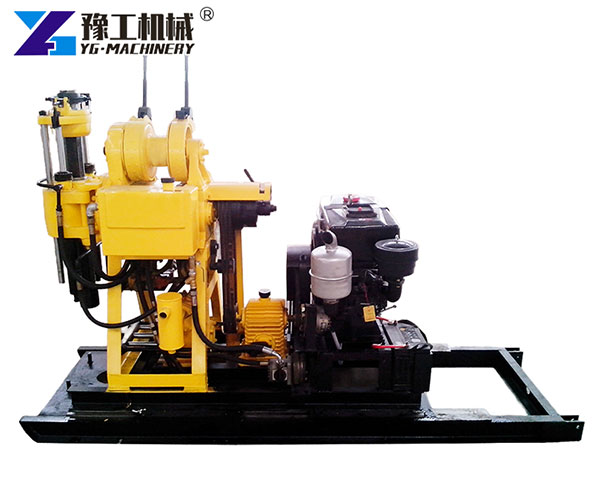

What Is A Core Drilling Rig?

A core drilling rig drills cylindrical samples from rock. The drill cuts a core and brings it out for lab tests. Core drills use diamond bits for hard rock. Main parts include:

- Drill head and motor

- Drill rods and bits

- Hydraulic or electric power unit

- Control panel and feed system

A core drilling rig can be trailer-mounted, truck-mounted, or portable. Choose based on site access and depth needs.

Key Features And Advantages

Our rock core drilling machine delivers reliable results in even the toughest rocks. Main advantages:

- High Precision: keeps the core intact for lab work.

- Strong Power: handles hard rock and deep holes.

- Easy to Maintain: common spare parts and simple checks.

- Portable Options: small rigs move by pickup or tracked carrier.

- Low Fuel Use: Efficient hydraulic systems save cost.

These features help teams finish jobs faster and more safely.

Geological Drilling Equipment Applications

Geological drilling equipment helps many projects. Typical uses:

- Mineral exploration and mine planning.

- Tunnel and foundation site surveys.

- Environmental sampling for groundwater or contamination.

- Road and railway ground checks.

Field teams value rigs that work in cold, hot, or remote places. Our machines suit all these tasks.

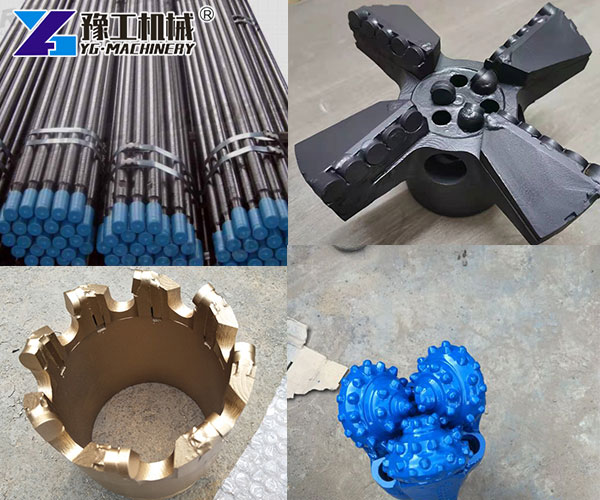

Diamond Core Drill Rig Options

For very hard rock, choose a diamond core drill rig. Diamond bits cut fast and last longer. Options we offer:

- Small diamond rigs for 50–150 mm cores.

- Mid-size rigs for 150–300 mm cores and deeper holes.

- Full hydraulic rigs for heavy-duty, continuous drilling.

We help pick the right size for your project. Bit type, rod diameter, and feed speed change with geology.

Portable Core Sampling Drilling Machine

A core sampling drilling machine for field work must be simple and tough. Portable models include:

- Light tracked units for rough terrain.

- Compact truck rigs for fast job changeover.

- Trailer rigs for road transport and storage.

Portable rigs reduce mobilization costs and speed up exploration. They also let small teams work alone safely.

Why Choose Our Rock Core Drilling Machine?

Choose our machines for these practical reasons:

- Proven Design: tested in mines and labs worldwide.

- Custom Options: we adjust depth, pipe diameter, and power.

- After-Sale Support: manuals, video training, and spare parts.

- Export Experience: clear export documents and safe packing for sea freight.

We know field problems and design machines for less downtime.

Contact Us

If you need a rock core drilling machine, tell us:

- Target hole diameter and depth.

- Power supply (diesel/hydraulic/electric).

- Work environment (cold, wet, remote).

We will recommend the right core drilling rig and send a fast quote. Get in touch to arrange a demo or brochure.

Contact us to get special offer now! WhatsApp/WeChat 008613837159132