What Is A Dredging Robot?

A Dredging Robot is an unmanned, remote-operated machine for river and lake cleaning. It removes silt, sludge, and waste without sending people into unsafe water. Compared with manual dredging or large barges, it is smaller, safer, and easier to deploy. It reduces crew on site, lowers fuel use, and works close to shore with less disturbance.

Contact us to get special offer now! WhatsApp/WeChat 008613837159132

Dredging Robot For Sale – YG Machinery

YG offers Dredging Robot for Sale with different power and duty levels to match your water body and sediment.

| Dimension: | 1220*890*520mm | Speed: | 2.5-4KM/h |

| Self Weight: | 120kg | Designed Load: | 100-300kg |

| Waterproof: | IP68 | Rated Torque: | 100-500 NM |

| Track Width: | 130mm | Reducer Efficiency: | 65-85% |

| Gear Ratio: | 1:10-1:40 | Motor Voltage: | 380ACV (customized as local voltage) |

| Motor: | 0.75-1.5KW*2 | Climbing Ability: | ≤30°(can climb stairs) |

| Motor Rated Speed: | 1500r/min | Maximum Span: | 620mm |

| Cable Control Distance: | Standard 50m, maximum 150m | Over-Obstacle Capacity: | 130mm |

| Maximum Underwater Depth: | 30m | Power Supply: | Generator or 380V power supply |

Our sediment dredging equipment lineup can be tailored to your job:

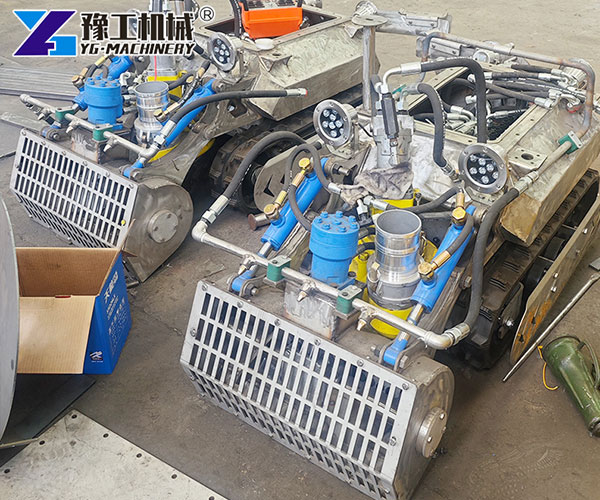

- Adjustable cutter heads and jet rings.

- Hose diameters range from 4–10 inches.

- Optional sonar, RTK, and flowmeters for production tracking.

- Shore dewatering systems (geotextile bags, cyclones, or presses).

How Does A Dredging Robot Work?

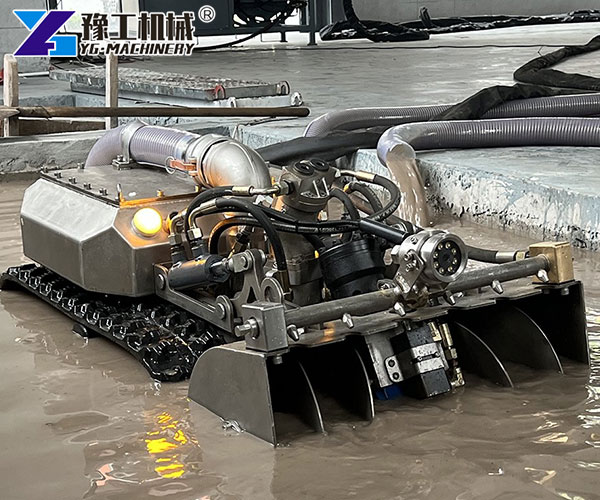

A Dredging Robot clears sediment through a simple but effective process:

- Pump Suction: A wear-resistant slurry pump pulls silt and sludge.

- Agitation: Cutter or jet nozzles loosen compacted sediment.

- Conveyance: Slurry flows through a hose to shore or a dewatering unit.

Main Components

- Propulsion System: Tracks or thrusters for stable movement.

- Pump Body: High-efficiency pump matched to sediment type.

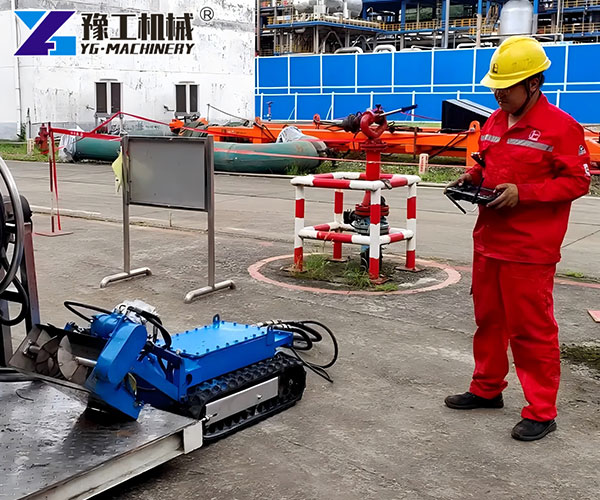

- Remote Control System: Handheld or console with live data.

- Positioning System: GPS/RTK and sonar help guide the path.

Remote Controlled Dredging Robot: Control And Positioning

A remote controlled dredging robot keeps operators safe on land. It supports:

- Real-time depth and heading display.

- Fixed-path auto steering or geo-fencing (optional).

- Alarms for pressure, temperature, and cable/hose tension.

Key Advantages Of Using A Dredging Robot

An unmanned dredging machine is controlled from land. Operators stand on the bank and use a console. Benefits include:

- No workers in the water, lower accident risk.

- Precise, targeted removal of sediment and debris.

- Small wake and low noise near communities.

- Easy transport by trailer or pickup.

Applications Of Dredging Robots

A Dredging Robot is versatile and works in many sites:

- River Desilting: Remove silt bars, restore flow, protect banks.

- Lakes and Ponds: Recover water depth in parks and resorts.

- Ports and Wharves: Clean berth edges without big barges.

- Industrial Ponds: Treat sludge in wastewater settling basins.

A river cleaning robot handles:

- Silt removal near bridges and intakes.

- Spot dredging around culverts and bends.

- Debris and light vegetation clearance before flood season.

Why Choose YG Dredging Robot

- High-Performance Build: Anti-wear pump, marine-grade coatings, sealed electrics.

- Proven Projects: Municipal rivers, resort lakes, and industrial ponds worldwide.

- Easy Service: Modular parts, quick-swap seals and liners, clear manuals.

- Expert Support: Sizing, deployment plan, and start-up guidance.

- Compliance: Options to meet local noise and emission rules.

Buying Guidance And Configuration Tips

To select the best Dredging Robot, consider:

- Water Body Size: Width, depth, and access points.

- Sediment Type: Silt, clay, sand, or mixed sludge.

- Throughput Target: Required flow rate and daily volume.

- Discharge Route: Hose length, lift height, and dewatering method.

- Power Source: Grid availability vs. diesel on remote sites.

- Data Needs: Production logging, GPS maps, turbidity goals.

YG Machinery Service

YG provides remote commissioning and on-site training (where available). We help you plan safe launch points, hose routing, and emission controls. Spare parts and wear kits are stocked. Routine checks are simple: pump inspection, seal check, grease points, and filter changes.

Tell us your site details and goals. Share water area, sediment type, target volume per day, hose distance, and power preference. Our team will size the pump, choose cutter and nozzle kits, and propose a delivery plan. Get a fast quote on a Dredging Robot package that saves time, lowers risk, and protects your waterway.

Contact us to get special offer now! WhatsApp/WeChat 008613837159132